Robot packing and stacking of timber bundles

Programmed Timber Supplies supply to users of bulk timber & timber components. Customers include wall frame & roof truss fabricators, furniture manufactures & importers, industrial manufacturers, packaging suppliers, distribution & logistic companies, independent & chain building material outlets and wholesale timber distributors.

Working closely with their clients to achieve the best outcome in terms of product grade & quality, supplied at the right time and priced to meet the highly competitive market in which they operate.

A well programmed timber supply is always their goal.

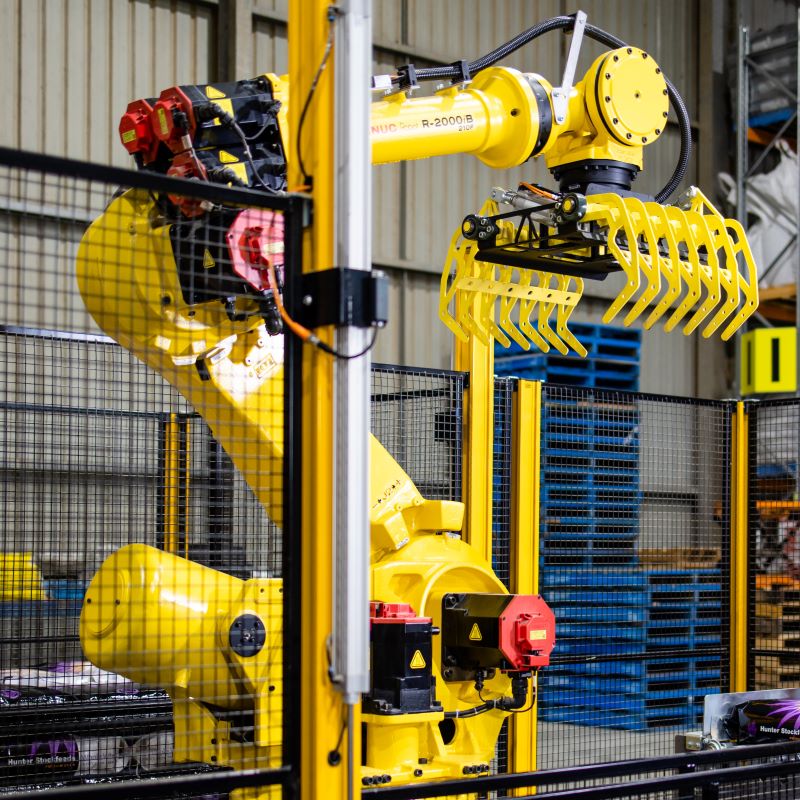

Wanting to meet expected future growth, a robot packing and stacking solution was sourced to handle the output of their docking system.

Implementing a robot into production also eliminates the numerous OHS risks associated with the task.

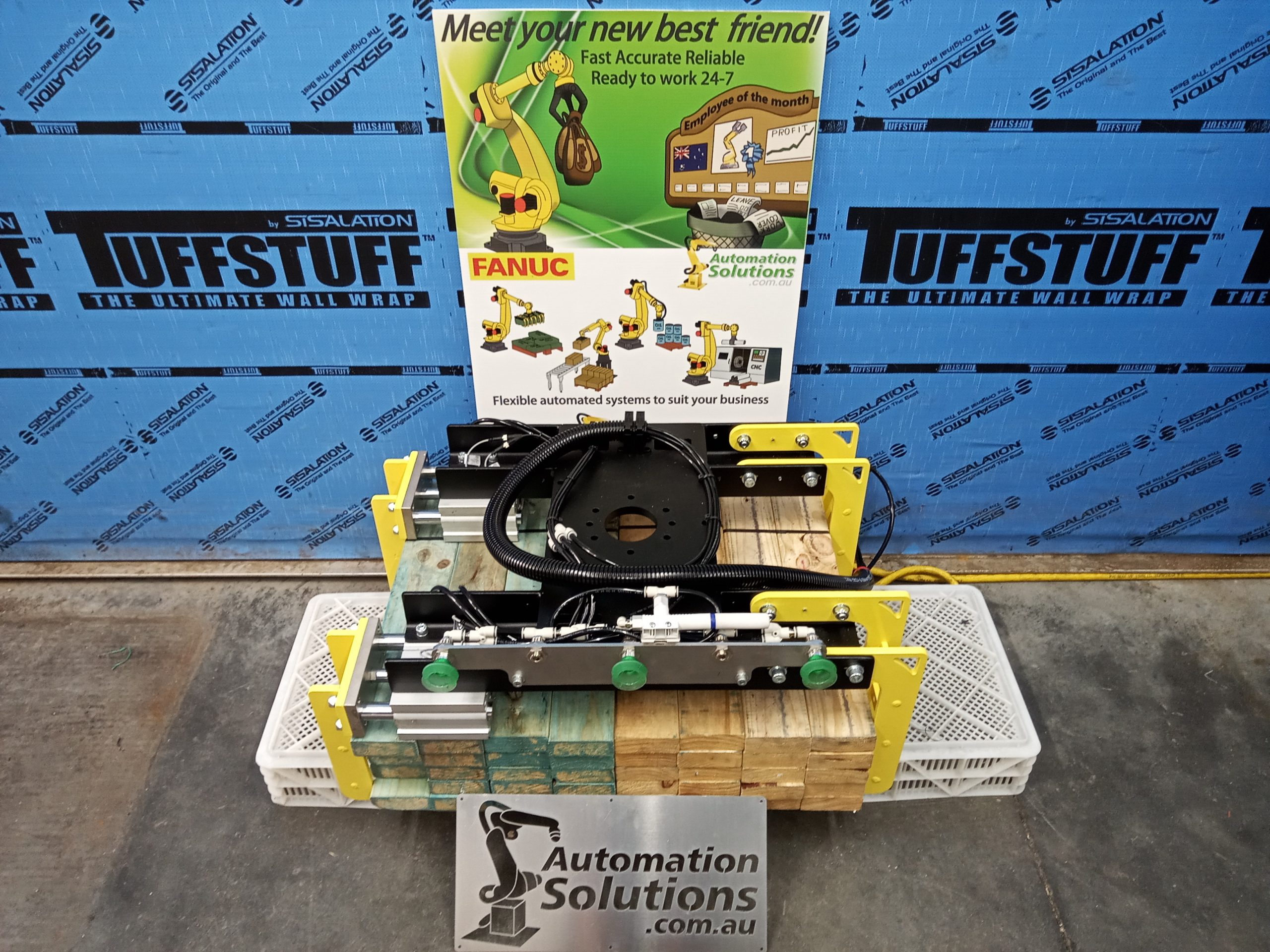

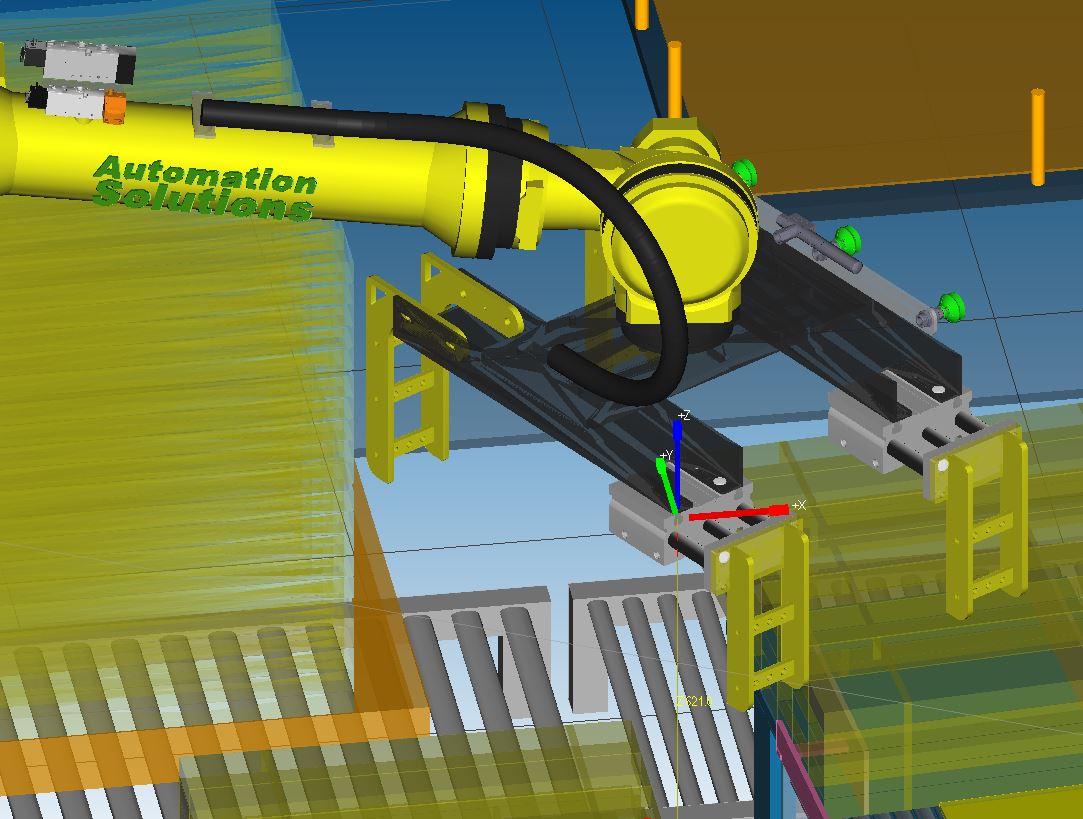

The robotic timber handling system has been designed to accommodate various sized timber products that go through the line, and utilises a heavy duty robotic timber gripper. The gripper is multi function, also used to place a slip sheet between layers.

The robot palletiser operates with no external PLC, making a very simple low cost implementation with high ROI for the owners at Programmed Timber Supplies.

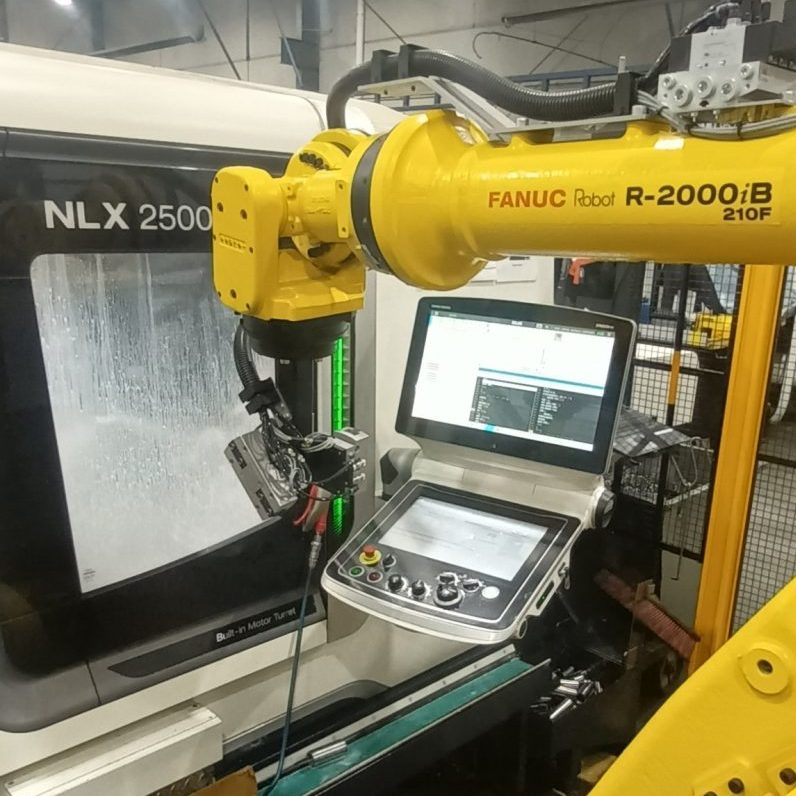

The Fanuc R2000iC/165F robot is perfect for palletizing applications due to its large working envelope, high payload, and high speed.

If you are also looking for an intelligent cost effective automated solution to palletise or stack timber products, then Automation Solutions has a solution for you.

Contact us today!