Enhance Your Warehouse Efficiency with Advanced Automation

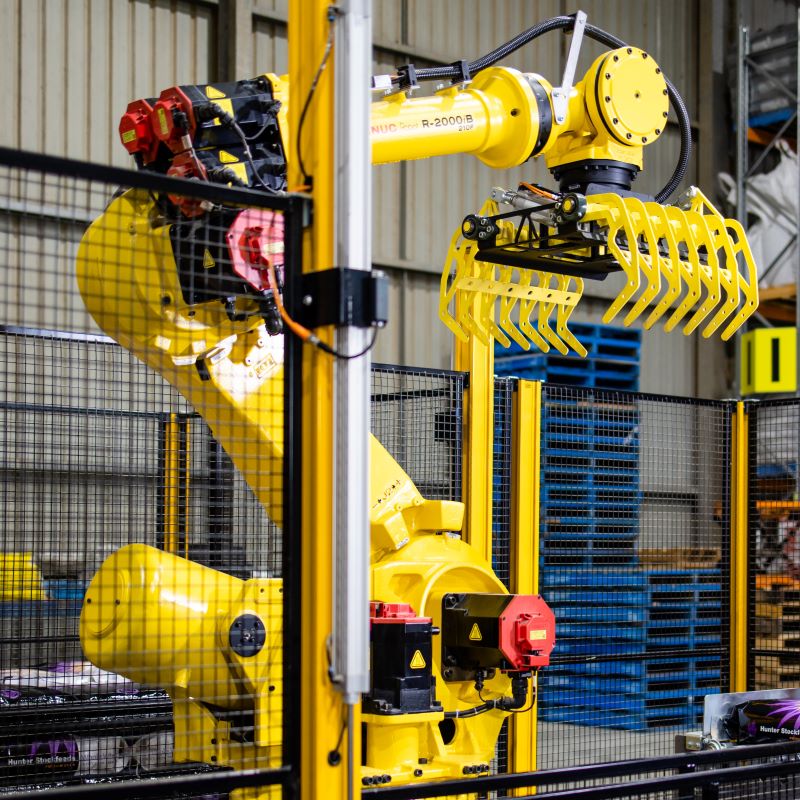

Introduction to Robot Palletising Systems

In the ever-evolving landscape of modern logistics and warehousing, efficiency and productivity are paramount. Robot palletising systems are at the forefront of this transformation, ensuring that businesses can streamline their operations while maintaining superior levels of precision and reliability. Whether you are in the manufacturing, food and beverage, pharmaceutical or consumer goods industries, our advanced robot palletising solutions can be tailored to meet a variety of palletising and logistics challenges.

What Are Robot Palletising Systems?

Robot palletising systems leverage cutting-edge robotics and artificial intelligence to automate the process of stacking and arranging products on pallets. Unlike traditional palletising solutions that often introduce bottlenecks and increase labor costs, robotic systems offer adaptability, improved cycle times, and enhanced consistency.

Key Benefits of Robot Palletising Systems:

Flexibility in Handling Products: Modern robots can handle a wide range of product dimensions and weight, allowing for versatility across different packaging types.

Increased Productivity: Automated systems can operate continuously, reducing the downtime typically associated with manual palletising.

Reduced Labor Costs: By minimizing the dependency on manual labor, businesses can significantly cut operational expenses while redirecting workers to more value-added tasks.

High Precision and Consistency: Automated systems ensure that products are stacked in a consistent manner, reducing the risk of product damage during transportation.

Real-time Monitoring and Analytics: Many advanced palletising systems come equipped with software that tracks performance metrics and offers insights for continuous improvement.

Applications of Robot Palletising Systems

Robot palletising systems can be integrated into various industries to optimize production and distribution. Here are some common applications:

Manufacturing: Streamaline the end-of-line processes by ensuring no bottleneck occurs during loading and shipping.

Food and Beverage Industry: Effortlessly palletise products ranging from bottles and cans to boxes and cases, while adhering to stringent safety protocols.

Pharmaceutical and Cosmetics: Automate handling sensitive and varied packaging sizes, ensuring safety and compliance.

Consumer Goods: Efficiently packaging products for retail distribution, resulting in faster turnaround and enhanced consumer satisfaction.

Why Choose Us for Your Robot Palletising Solutions?

When seeking a provider for your robot palletising systems, consider our comprehensive approach:

Custom Solutions: Our experts work alongside your team to develop tailored solutions that align with your specific needs and production capabilities.

Nationwide Support: Our dedicated service team is available around the clock, providing timely support and maintenance for optimal performance.

State-of-the-art Technology: Utilizing the latest advancements in robotic technology and AI, our systems are designed to ensure you stay competitive in your industry.

Cost-effective Innovations: We blend cutting-edge technology with an understanding of cost efficiencies; our solutions yield high returns on investment over time.

Investing in advanced robot palletising systems is an intelligent step towards enhancing operational efficiency, reducing costs, and optimizing the supply chain. With proven applications across various industries and a commitment to top-tier automation technology, our solutions are designed to elevate your warehousing capabilities.

Transform your palletising process today and unlock the full potential of automation. Contact us to learn more about our robot palletising systems and how we can partner with you for success!

Contact Brett at Automation Solutions for more information on 0402 498 454 or visit automationsolutions.com.au