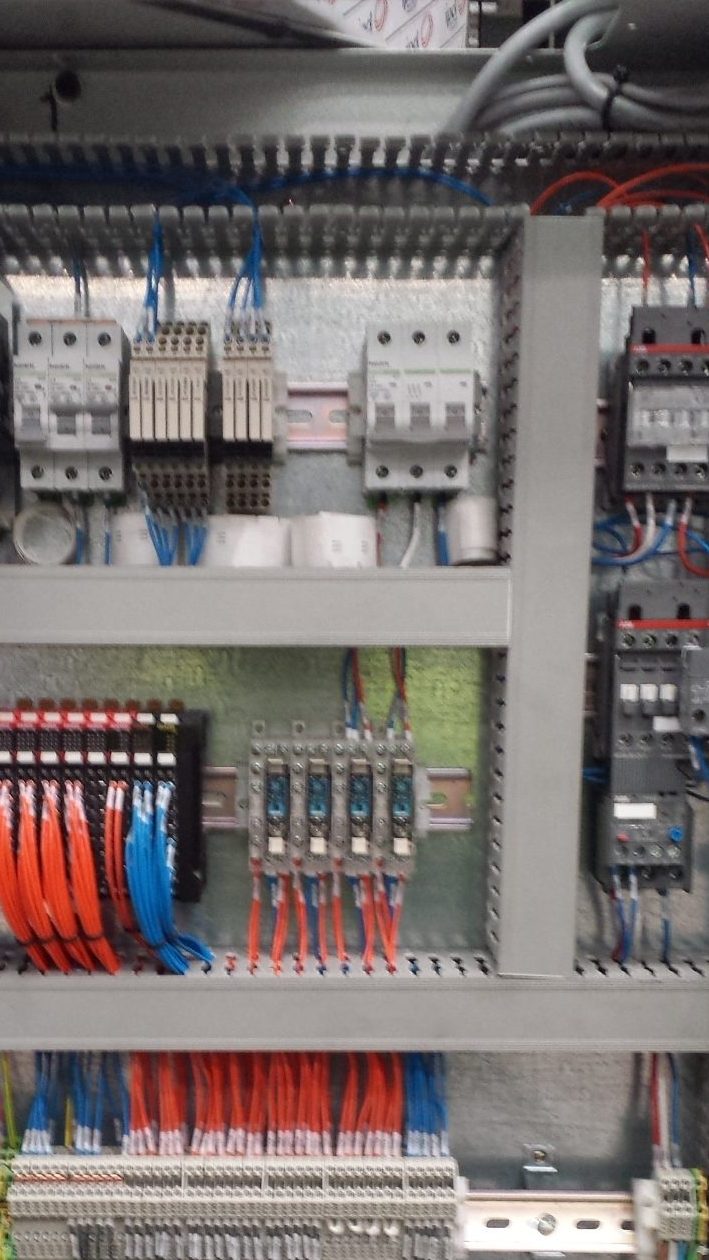

Replace your outdated PLC to improve machine reliability and uptime.

The Key Benefits of Upgrading Your PLC System

In today’s fast-paced industrial environment, maintaining a competitive edge is crucial, and one way to achieve this is by upgrading your Programmable Logic Controller (PLC) system. Here are some compelling benefits of making this transition:

- Enhanced Performance and Speed: Modern PLCs are designed with advanced processing capabilities, allowing for faster execution of control tasks. This leads to improved response times and overall system efficiency.

- Increased Reliability: Upgrading often involves transitioning to newer technologies that offer greater reliability and durability, significantly reducing the risk of system failures and downtime.

- Greater Data Handling: Newer PLCs can handle larger volumes of data, which is essential for industries increasingly reliant on data analytics. This capability enables more comprehensive monitoring and optimization of processes.

- Improved Diagnostic Features: Modern PLCs come equipped with advanced diagnostic tools that simplify troubleshooting and maintenance, helping reduce response times to issues and minimizing operational interruptions.

- Seamless IoT Integration: Upgrading allows facilities to harness the power of IoT, providing real-time data access, remote monitoring, and enhanced communication with other devices in the network.

- Enhanced Security: With the rise of cyber threats in industrial settings, newer PLCs offer improved security features, including encrypted communications and better access controls, protecting your system from unauthorized access.

- Support for Advanced Automation: Upgrading opens up opportunities to implement more sophisticated automation strategies, such as machine learning and artificial intelligence, which can lead to increased productivity and efficiency.

- User-Friendly Interfaces: Modern PLC systems feature intuitive interfaces that simplify operation and maintenance, making it easier for technicians to work with complex automation processes.

- Compliance and Standards: Newer PLCs often comply with the latest industry standards and regulations, ensuring that your facility remains compliant and up-to-date with safety protocols.

- Cost Savings: While the initial investment in upgrading may seem significant, the long-term savings through increased efficiency, reduced downtimes, and improved reliability can result in substantial cost reductions.

In conclusion, upgrading your PLC system is not just a technical improvement; it’s an investment in the future of your business. By embracing the latest technologies, you can enhance reliability, improve operational efficiency, and remain competitive in today’s market. If you’re considering an upgrade, now is the perfect time to explore the options available and take your automation processes to the next level!

Contact Brett at Automation Solutions for more information on 0402 498 454 or visit automationsolutions.com.au