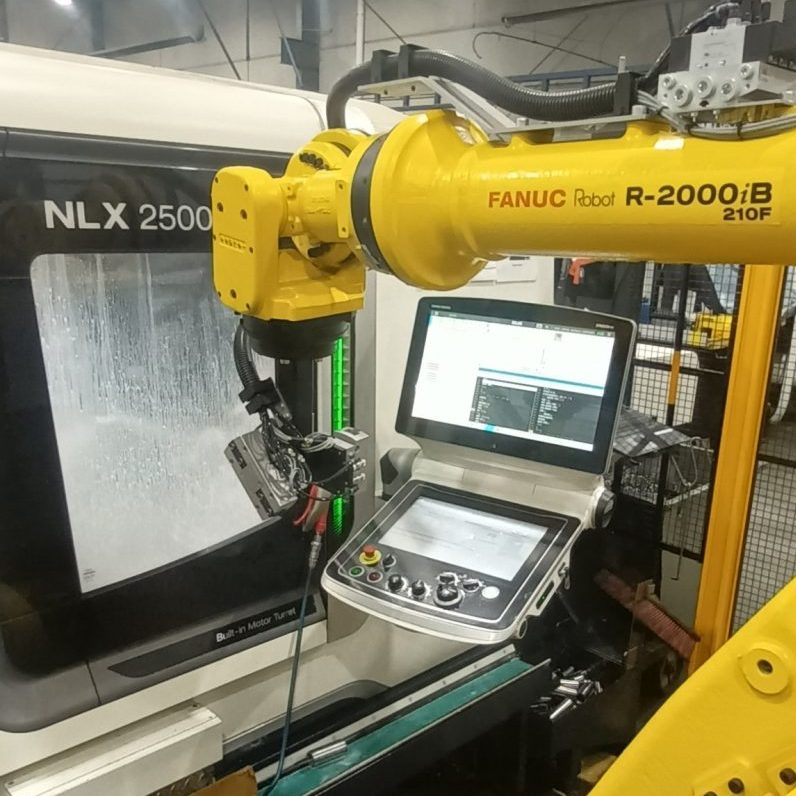

Fully-automated Robotic Machine Tending Systems

Robot machine tending systems represent a pioneering solution that combines automated robotics with minimal human intervention for higher levels of productivity. These systems are designed to handle various tasks, such as loading and unloading parts in CNC machines, or injection moulding machines, ensuring streamlined operations and reduced labor costs.

Remove the risks associated with repetitive lifting of heavy objects, and the proximity to large dangerous machines.

Let’s Talk Benefits

Operating speed and efficiency

Able to reliably tend machines at higher-speeds without fatigue, the speed and efficiency with which machine tending robots operate is unmatched.

Improved quality and repeatability

Many previous machine loading projects have allowed us to hone our programs, the consistency of loading your machines will be at new levels, ensuring your products are kept safe damage free.

Workplace health and safety

Smart as well as safe, robots and cobots operate safely without humans for operation, automating these particularly dangerous and risk-prone tasks will help in WHS risk reduction

Increased Productivity

Automated systems can operate continuously, reducing the downtime typically associated with manual loading and unloading tasks.

Reduced Labor Costs

By minimizing the dependency on manual labor, businesses can significantly cut operational expenses while redirecting workers to more value-added tasks.

Flexibility in Handling Products

Modern robots can handle a wide range of product dimensions and weight, allowing for versatility across different product types.

Our Design Approach

Working with Automation Solutions

STEP 01

Contact us for a Quote

Provide us with general details of your project and we can offer initial concept costing

STEP 02

Investigate the Project

We will further study the project to provide an effective, tailored solution

STEP 03

Develop Solution

We remain in contact throughout the process, keeping you well-informed on project development

STEP 04

Implement Onsite

Installation will be managed to provide as little impact to production as possible

Contact us today with your project details..

How Robot Machine Tending Systems Drive Competitive Advantage

Employing robot machine tending systems is more than just upgrading your machinery; it’s about transforming the way you operate.

- Streamlined Operations: Minimize bottlenecks in production processes by allowing robots to take over monotonous loading and unloading tasks.

- Employee Focus: Free your skilled workforce from repetitive tasks, allowing them to focus on more strategic initiatives and innovations that drive your business forward.

- Market Responsiveness: In a constantly changing market, the adaptability of robotic systems empowers businesses to respond effectively to shifts in customer demands and product variations.

Why Choose a Robot Machine Tending System?

- 1. Enhanced Efficiency and Productivity

Robot machine tending systems operate continuously, working around the clock without fatigue, which drastically increases production rates. By minimizing downtime, businesses can produce higher quantities of finished goods with max efficiency.

- 2. Improved Precision and Quality Control

With advanced programming and artificial intelligence, robot machine tending systems guarantee consistent quality across all processes. The risk of human error is significantly reduced, resulting in high precision manufacturing that meets stringent quality standards.

- 3. Cost Savings

While the initial investment in robot machine tending technology may seem significant, the long-term savings are undeniable. Reduce labor costs, eliminate costly mistakes, and optimize wall-clock time in production schedules to enhance your bottom line.

- 4. Flexibility and Scalability

Modern robot tending systems are designed to be versatile. They can easily adapt to different tasks or products, making them suitable for a wide range of manufacturing requirements. As your business grows, your robotic systems can scale accordingly, allowing for easy expansions without major overhauls.

Invest in your business

Investing in robot machine tending systems not only modernizes your manufacturing processes but shoots your organization ahead of competitors by improving efficiency, quality, and cost-effectiveness. As industries evolve towards greater manufacturing automation, ensure your operations are equipped to harness the full potential of robotic technology. Discover how you can implement this transformational change in your manufacturing facility today!

Why Choose Us for Your Robot Machine Tending Solutions?

When seeking a provider for your robot loading/unloading system, consider our comprehensive approach:

- Custom Solutions: Our experts work alongside your team to develop tailored solutions that align with your specific needs and production capabilities.

- Nationwide Support: Our dedicated service team is available around the clock, providing timely support and maintenance for optimal performance.

- State-of-the-art Technology: Utilizing the latest advancements in robotic technology and AI, our systems are designed to ensure you stay competitive in your industry.

- Cost-effective Innovations: We blend cutting-edge technology with an understanding of cost efficiencies; our solutions yield high returns on investment over time.