Robotic packaging cell

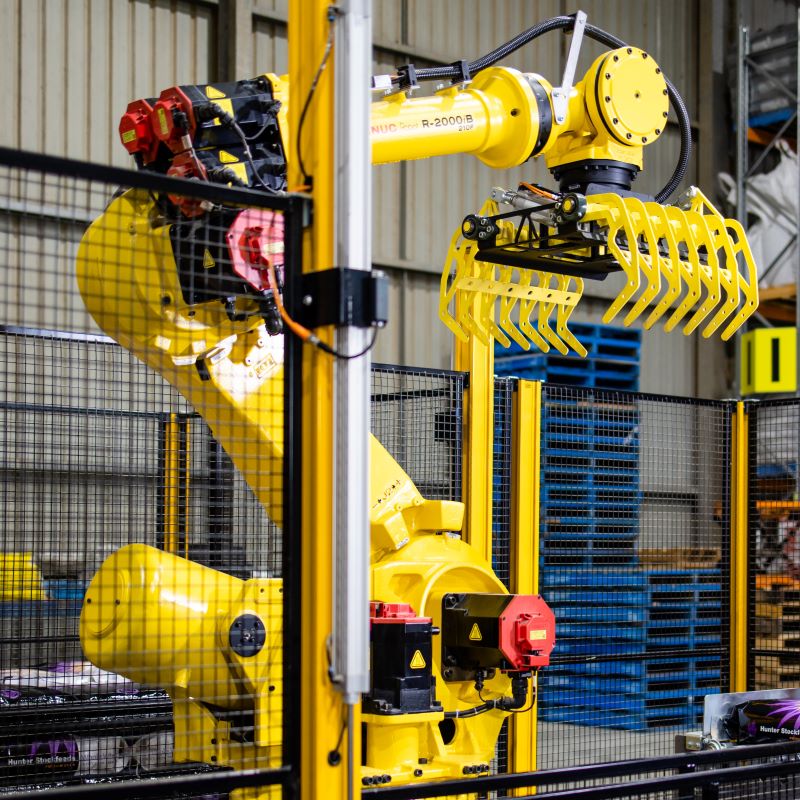

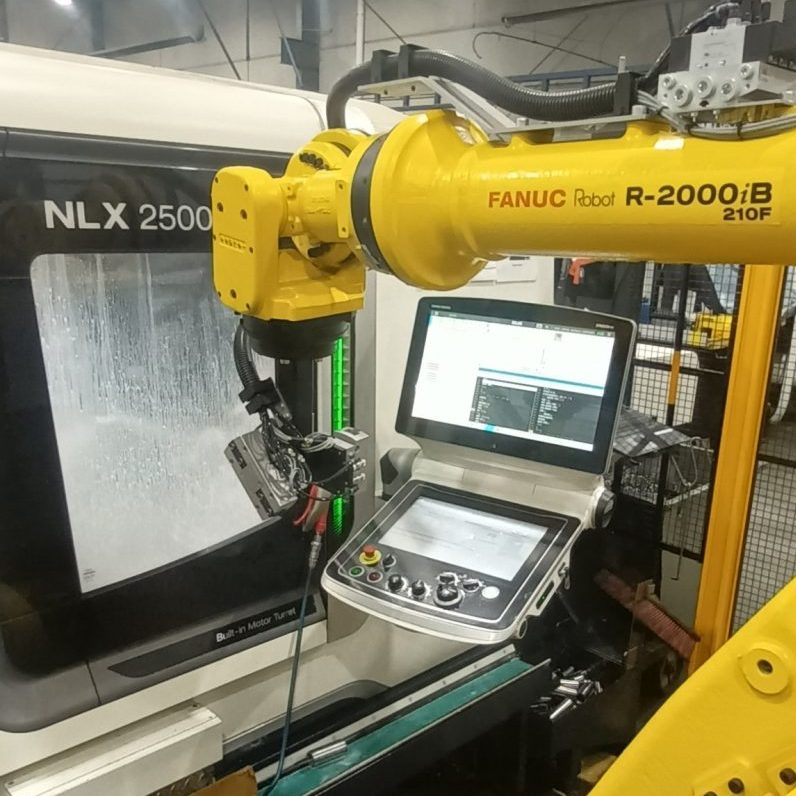

Robot Palletising cell

Westbuild Group in Perth offers a diverse and expanding range of building products for the professional, handyman and DIY market, as well as the ceramic tile industry. For this reason a flexible automation solution in the robotic programming cell was required to handle the varying sized products quickly and easily to ensure quick turn around time from order receipt to delivery.

A Fanuc M710iC robotic palletising cell performs numerous tasks as well as additional automation controlled from the robot controllers internal PLC.

For a robot to successfully pick and place a bag on a filling spout, the bags need to be of an acceptable quality. The consistency of the material (porosity) needs to be kept high for the robot process. Incorrect folds, or glue smears keeping the spout closed will lead to either ‘miss picks’ or ‘miss loads’, harming the overall production rate. talk to your bag supplier.