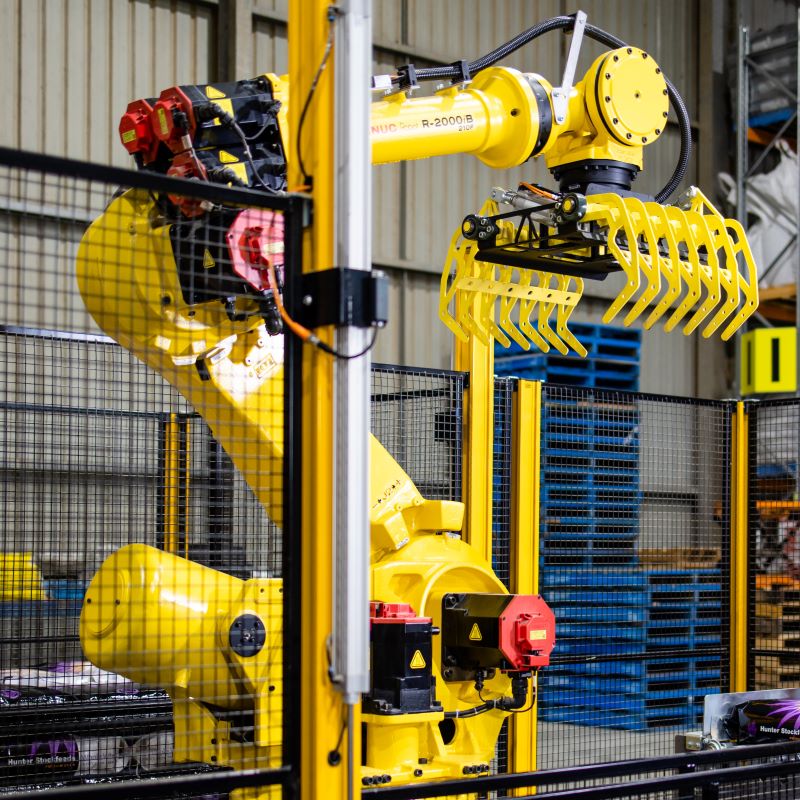

Press Brake Tending Robot

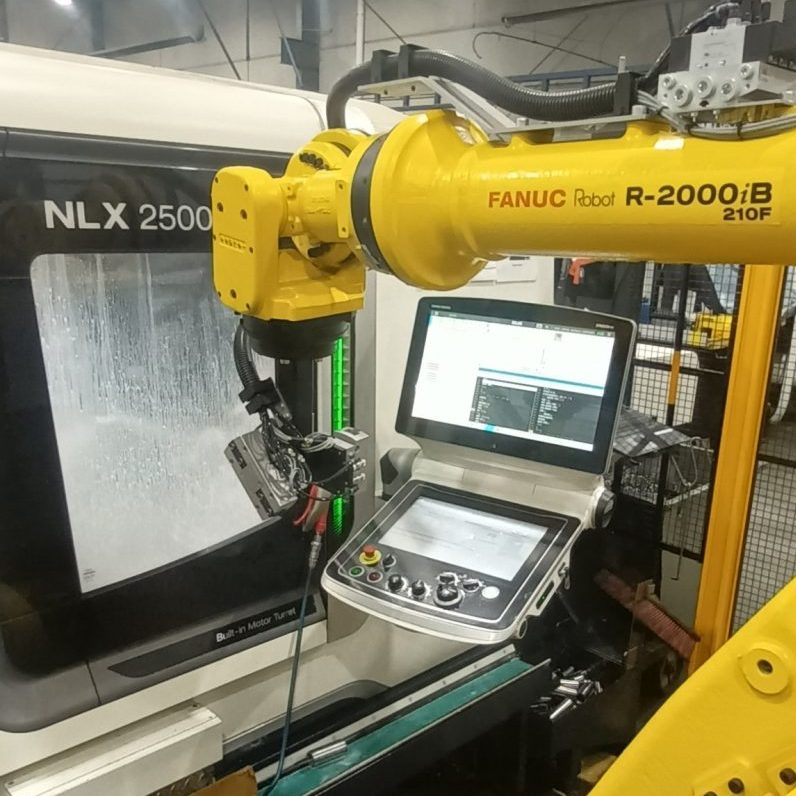

Fast and efficient, a press brake tending robot is a smart choice to improve production in your factory.

Triple M tray Bodies is Australia’s most trusted and proven tray body manufacturer with over 50 years of experience and 800,000 ute trays sold.

Wanting to meet expected future growth, a press brake tending robot cell was sourced to handle the output of their production system.

Implementing a robot into production also eliminates the many OHS risks associated with the task of folding sheetmetal items.

The gripper for the robotic press brake tending system has been designed to accommodate various sized products that go through the line.

If you are also looking for an intelligent cost effective automated solution to tend your press brake or other CNC machine, then Automation Solutions has a solution for you.

Contact us today!