Robot spraying of cow teats for Mastitis prevention

Inionba Pastoral in Kyabram Victoria have installed a robot to handle the process of spraying cow teats to prevent mastitis infection in their herd.

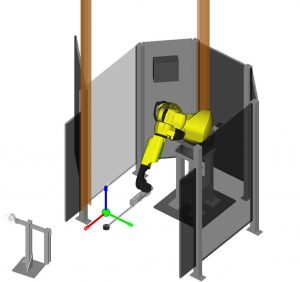

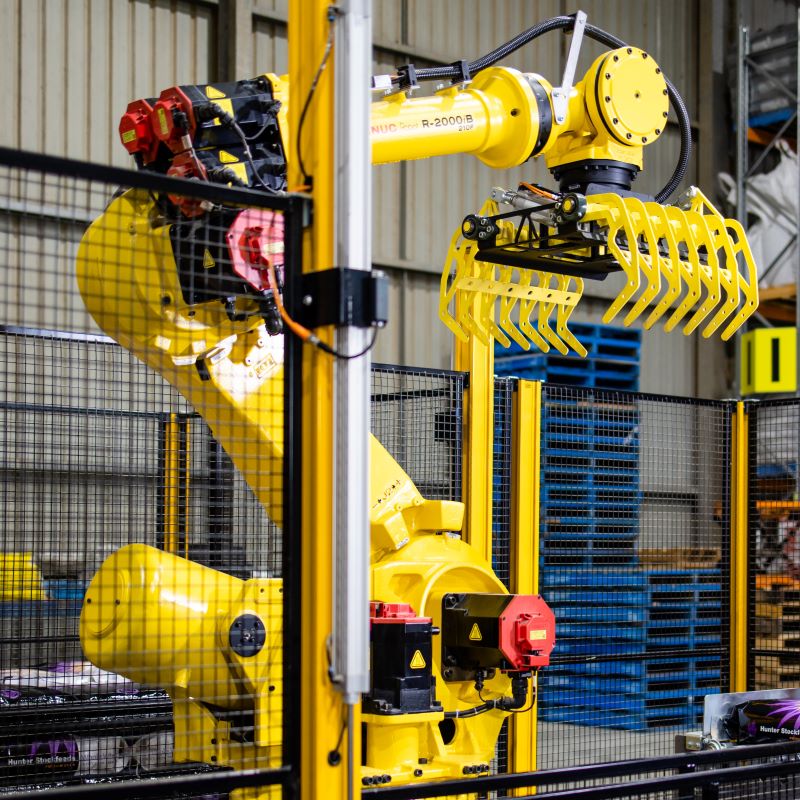

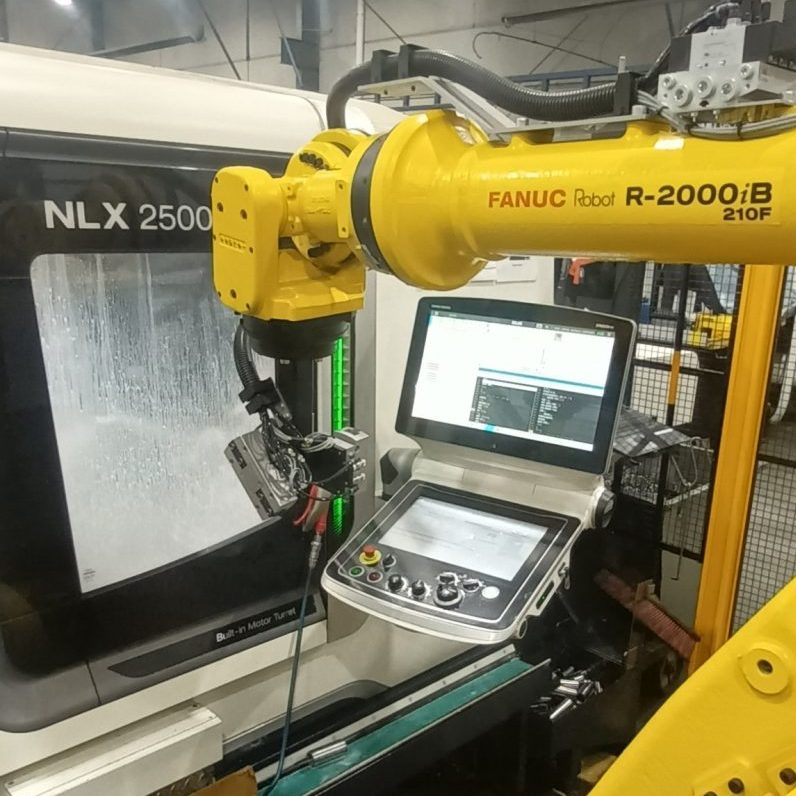

A Fanuc M20iD was selected for the task due to its compact size and generous reach, and was supplied with an integrated encoder which gives fully synchronized movement with the rotary platform.

This installation is on a 100 stall rotary platform, and the robot comfortably performs its function with spray time of ~2 seconds and total stall speed of ~4 seconds.

With its relative low cost of implementation, it makes it just as suitable for smaller platforms and herds.

Implementing the robot into this process frees up available labour to complete other varying day to day tasks and also eliminates the numerous OHS risks associated with the task.

The robotic teat spraying system has been designed to accommodate various sized udders, and utilises smart, robust, industrial sensors to identify when and what spray path to follow, making it far more suitable for Australian milking parlors.

The robot system operates with no external PLC, making a very simple low cost implementation with high ROI for the owners of Inionba Pastoral.

The Fanuc M20iD/35 robot is perfect for teat spraying applications due to its large working envelope, small foot print, and high speed. Fitted with SDLP, it is suitable for the rigors of a dairy parlor.

If you are also looking for an intelligent cost effective automated solution to spray cow teats or other dairy processes, then Automation Solutions has a solution for you.

Contact us today!